Subscribe now and get our latest blog and video content delivered straight to your inbox.

Understanding Type 1 and Type 2 Stove Boards

By Mike McKinney / Louis Greubel

Apr 12, 2024

Wood heating appliances are great. People use them for everything from adding a little ambiance to heating their entire homes. Wood stoves in particular are popular, but they can also be dangerous — especially if they’re not insulated correctly. And that’s where stove boards come in.

Wood stoves require some kind of insulating pad beneath (and sometimes around) the appliance. Floors and walls around the stove are almost always combustible, and stove boards ensure these flammable materials don’t catch fire.

There are two types of board available: type 1 stove boards and type 2 stove boards. But what’s the difference between each type, and when do you need to use one over the other?

At HY-C, we manufacture type 2 stove boards. And in this guide, we’re going to cover the differences between those and their type 1 counterparts. We’ll explain their insulating properties, the materials from which they’re made, and much more.

By the time you’re finished with this guide, you’ll understand exactly which kind of stove board you need for your wood heating appliance.

What Are Stove Boards Made Of?

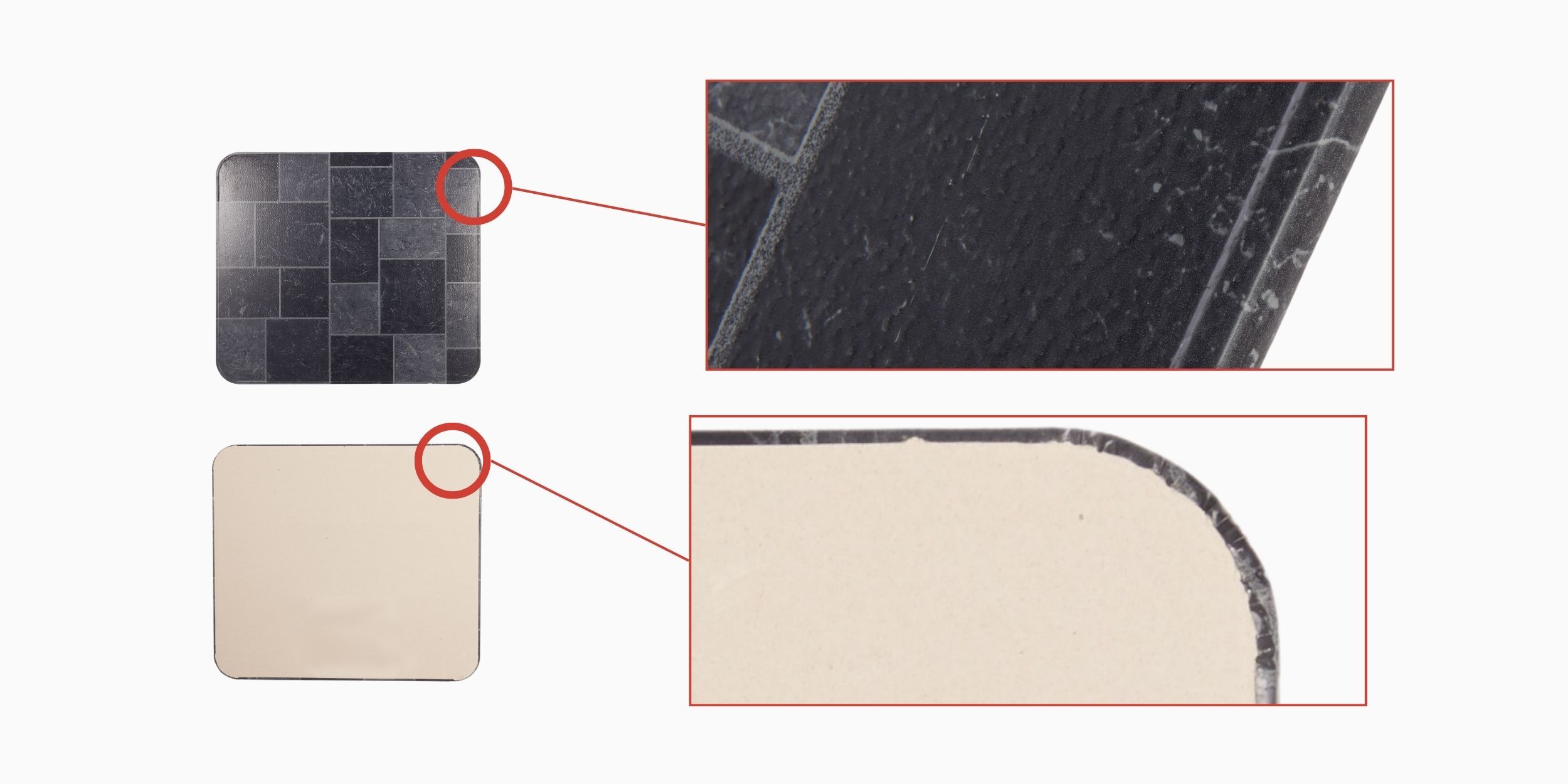

Stove boards are pretty simple products. They consist of steel wrapped tightly around some kind of fiber-based material that gives the board its structure. The difference between type 1 and type 2 stove boards lies in the difference between these fiber-based materials.

Type 1 stove boards offer a lower level of protection than type 2 stove boards. As such, type 1 stove boards use a much lighter, less heat-resistant fiber material. Some type 1 stove boards, for example, use a sound-deadening board manufactured by BlueLinx.

Type 2 stove boards, on the other hand, provide a higher level of heat and thermal protection. Their fiber core is much more robust. Our type 2 boards utilize a mineral fiber board called Micore® SB manufactured by USG.

Why Do You Need a Stove Board?

In order to understand type 1 and type 2 stove boards’ protective capabilities, we need to understand the units by which those capabilities are measured. There are 3 different ways heat moves from one object to another:

- Radiation — the transfer of heat through electromagnetic waves (instead of particles)

- Convection — the transfer of heat through a liquid or a gas

- Conduction — the transfer of heat between objects in contact with one another

With stove boards, conduction is the primary focus. As a heating appliance radiates heat, that heat is conducted by the structure of the home around it. This is potentially dangerous, as common building materials tend to be highly flammable.

Instead, you need to place a stove board in the spots around the heating appliance that absorb the most heat. These spots typically wind up being the floor under the appliance and the wall behind the appliance.

The stove board winds up absorbing the heat instead of the wall or floor. This means the boards themselves need to conduct heat to ensure the floor and walls don’t get too hot. There’s a special measurement of this kind of conduction called R-value.

R-Value

R-value is a thermal resistance value. It measures the resistance of an object to conductive heat flow. The higher an object’s R-value, the better a thermal insulator it is.

R-value is of interest for all kinds of insulating materials. In homebuilding, contractors pay close attention to the R-value of roof shingles, drywall insulation, and attic insulation. These materials need to hold heat in a home during the winter (and keep it out during the summer).

To give you some context for the scale of thermal resistance, here are the R-values of some common materials:

- ⅛” of glass: 0.03

- 1” of stone: 0.08

- 1” of brick: 0.20

- ¼” of ceramic tile: 0.25

- ½” of cement: 0.39

- ½” of drywall: 0.45

In order to be effective heating appliance insulators, stove boards need to have an R-value of at least 1.0.

Type 1 Stove Boards

As we mentioned earlier, type 1 stove boards are made from fiberboard wrapped in steel. Some type 1 boards are even composed solely from steel. These boards feature an R-value less than 1.0. As a result, they do not meet the thermal protection requirements for wood stoves and other heating appliances.

Why would you use one at all, then? Despite their lower level of protection, type 1 stove boards do still provide protection against embers. As coals, sparks, and burning wood fall out of your heater, the last thing you want is for them to contact a combustible wall or floor.

Type 1 stove boards effectively shield combustible material from these embers. While they don’t meet the thermal protection levels recommended by wood heating appliance manufacturers, they will still prevent embers from causing fires if they make their way outside the stove or furnace.

Type 2 Stove Boards

Maintaining an R-value above 1.0, type 2 stove boards offer both thermal and ember protection. In fact, manufacturers tend to make their stove boards to exceed this 1.0 R-value requirement to ensure extra protection.

Our type 2 stove boards manufactured under our Shelter brand, for example, maintain an R-value of 1.56. Imperial — another stove board manufacturer — makes type two stove boards with an R-value of 1.50.

Type 2 stove boards are approved by UL Solutions (formerly Underwriters Laboratories) for use with wood stoves, wood furnaces, pellet stoves, fireplaces, and more heating appliances.

Should You Get a Type 1 or Type 2 Stove Board?

Understanding stove boards means understanding a little bit of the complicated science behind them. At this point, though, you may be saying, “I’m not a physicist and I don’t care about thermodynamics. I just want to know which type of stove board to get.”

Luckily, heating appliance manufacturers will tell you which kind of stove board their appliance requires. It’s really that simple. Just remember that if an appliance requires a type 2 stove board, you should never use a type 1 instead. If an appliance requires a type 1 board, you can use either one.

At HY-C, we manufacture both types of stove boards in a variety of sizes and in three different colors. Whether you simply need ember protection or you require thermal protection too, we’ll have the boards to cover your heater.

But how much will you wind up paying for your stove board?

Our stove board cost guide lays out the retail prices for all of the boards we make. Use it to budget, plan ahead, and ensure your wood heating appliance is as safe as possible.